Mid-Am Metal Forming

Mid-Am Metal Forming is the industry leader in metal stretch forming, bending, metal fabrication, and painting services for aerospace, automotive, marine and architectural needs. Our expertise stretches from simple to exotic designs and includes extruded, brake formed, roll formed, sheet or drawn techniques. Arched windows, spiral and radius handrails, barrel vault skylights, aircraft parts – the possibilities are endless. We’ve developed an incomparable reputation for quality by providing all the expertise and assistance required to handle even the toughest curved metal challenges. If Mid-Am Metal Forming can’t do it, chances are, it can’t be done.

Services

- Stretch Forming

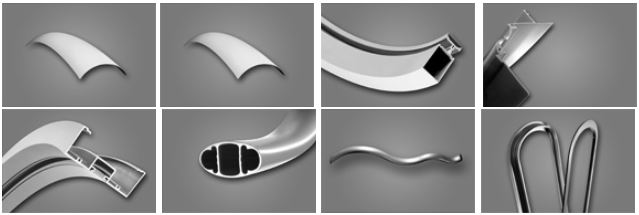

The quality workmanship of Mid-Am Metal Forming’s stretch forming process is unparalleled. We consistently produce distortion-free curved metal that meets or exceeds our customers’ specifications and tolerance requirements in almost any shape or cross-section. Stretch your imagination and we’ll make it a reality.

From architecture to air, land, rail, water or space, our stretch forming capabilities are as diverse as our customer base. From simple to exotic designs, we have yet to see a design that we can’t bring to life.

- Paint

Mid-Am Metal Forming is proud to offer painted aluminum direct from our facilities, which can save you time and money in material handling. We have a long history of applying superior coatings to aluminum, including liquid and powder paints that meet or exceed AAMA 2605, 2604, and 2603 specifications.

Mid-Am Metal Forming is proud to be an approved applicator for Sherwin Williams, PPG, and AkzoNobel products.

We offer in-house matching for 70% PVDF liquid paints, including specialty paints containing micas, allowing us to be responsive to customers’ needs on any scope of job. Matching air-dry systems are available for field touch-ups.

Our horizontal line is capable of handling brake metal shapes, flat sheets, custom fabricated components, curved shapes, and straight extrusions up to 290” long. We utilize a combination of both rotary atomizers and manual spray to ensure each piece receives individual attention.

Mid-Am Metal Forming provides the experience and expertise you need in applying architectural coatings, giving you and your customers the quality you expect and deserve.

Conversion Coating

Our multistage aluminum pretreatment process sees the material submerged in hexavalent chromium, ensuring the metal will be protected from corrosion even on unexposed surfaces that do not require paint coverage. Chrome pretreatment provides excellent corrosion protection from severe environments.

Many customers have us apply this coating, also known as Alodine, to aluminum when the pieces will be unseen but nevertheless require protection against the elements.

- Hollow Metal

Mid-Am Metal Forming gives our customers the design freedom they are looking for by providing curved hollow metal to any size, shape or arrangement that their project requires. Our process curves the length in one continuous piece eliminating the need for multiple cuts and Bondo© on the finished product. From single or multiple openings to curved or arched heads, we have the expertise and experience to meet even the toughest curving challenges.

- Brake Metal

From simple brackets to finished painted panels unitized and ready to install, Mid-Am Metal Forming has the expertise to brake metal up to 16’. Each of our facilities utilize the latest state-of-the-art machinery to ensure accuracy and consistency whether you need a single part, or a large production run and our quality control system assures you that your finished product meets the specification and tolerances you demand.

- Handrail & Staircases

Curved metal handrails and staircases by Mid-Am Metal Forming make it possible for you to design a stairway fit for heaven. Our curving process allows us to bend both simple, single plane bends for balcony landings to true spiral contours. To help ensure project accuracy, our expert team builds a full-scale mock-up of your design to ensure proper radius twist and angle that will align with the steel and glass at time of assembly. At Mid-Am Metal Forming, we proudly offer our customers the expertise and assistance required to handle even the toughest curved metal challenges.

- Fabrication

At Mid-Am Metal Forming our commitment to your design doesn’t end at the curved metal product. Our experienced fabrication team can trim, notch, drill, weld and even assemble any job. We can also go as far as to build a full-size mockup of your project, to provide you with pre-construct match mark, tear back down and ship complete and ready for installation to reduce your time and effort in the field. Further proof as to how we’ve built an incomparable reputation for quality.

- Water Jetting

- End Trim

- Notching

- Drilling

- Assembly

- Welding

- Painting

Mid-Am Metal Forming is proud to offer painted metal, up to 36′, ready for fabrication and installation direct from our facilities saving you time and money in job handling. Our full mix-and-match services enable us to match colors on virtually any job with quality paints using solvent systems, including jobs that require 70% Kynar that meets or exceeds AAMA 2605 specifications or 50% Kynar that meets or exceeds AAMA 2604 specifications. We offer chrome pretreatment and proudly supply customers with matching air dry systems for touch-ups in the field. Mid-Am Metal Forming provides the experience and expertise you need in applying architectural coatings, including industrial bake paint and powder coating, assuring you a quality finish for your project.

Let’s connect:

Missouri (Corporate Office)

1108 Center Rd, Rogersville, MO 65742

PHONE: (800) 767-2884

Estimating contact: Patrick “Pat” Gardner | pgardner@mamf.com

Direct: (417) 929-0462 | Fax: (417) 753-2860